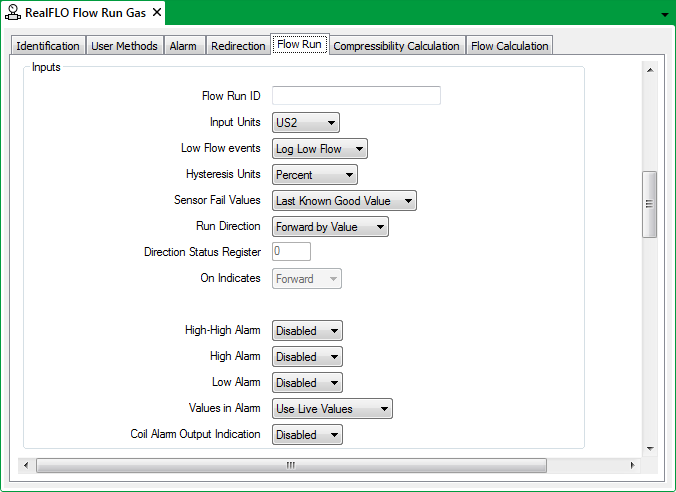

The Inputs properties section of the Flow Run tab is common to all three flow run types. You can configure these properties directly in ClearSCADA, or read the configuration into the ClearSCADA database (see Configure or Read the Flow Run Configuration).

Use the following fields within the Inputs section of the Flow Run tab to define the properties that are associated with the flow calculation’s input values:

- Flow Run ID—Enter the flow run identification string that identifies the flow run. The Flow Run ID is alpha-numeric for standard RealFLO and numeric for PEMEX RealFLO. Flow computer versions earlier than 6.00 accept a string up to 16 characters long. With flow computer versions 6.00 or newer, you can enter a string up to 32 characters long.

NOTE: The Flow Run ID is not supported in flow computers pre-version 6.00. RealFLO will not read or write the Flow Run ID when an older flow computer is detected.

- Input Units—Select the units of measurement of the input values for the flow run. Inputs may be measured in different units than the calculated results. You can use the units that are convenient to you for measuring inputs. The units available are determined by the flow run type:

Unit Types for Gas Flow Runs Unit Types for Liquid and Water Flow Runs IP Units IP Units US1 Units IP2 Units US2 Units IP3 Units US3 Units IP4 Units US4 Units IP5 Units US5 Units Metric 1 Units US6 Units Metric 2 Units US7 Units Metric 3 Units US8 Units Metric 4 Units PEMEX Units SI Units SI Units For more information about a particular unit, select the relevant entry in the table above.

- Low Flow Events—Select whether to log or ignore flow events that occur for the flow run. You can select the following from the combo box:

- Ignore—Select this option if the measured flow experiences low flow events as part of normal operation. Low Flow events are not added to the Alarm log and flow accumulation continues regardless of the flow rate.

- Log Low Flow—Select this option to add Low Flow events to the Alarm log.

- Hysteresis Units—Define how the hysteresis is configured for the High-High, High and Low alarms. The setting defines the level at which alarms are cleared when the input variable reading returns to a non-alarm state. This setting reduces nuisance alarms around the alarm threshold.

Select one of these options:

- Percent—Set the entry of hysteresis values as a percentage of the parameter range. Any value in the range 0 to 100 percent is valid.

- Engineering Units—Set the entry of hysteresis values as fixed engineering units. Any value in the full-scale range of the input variable is valid.

NOTE: When the AGA-7 flow calculation is used the alarm hysteresis is represented as a pulse input frequency. The pulse input is independent of the hysteresis units selection.

NOTE: For Liquid flow calculation this is only applied to Static Pressure Properties and Temperature Properties values.

NOTE: For Water flow calculations this in only applied to Temperature Properties values.

- Sensor Fail Value—Use this property to define the value that is used as the live input value when communication with a sensor is interrupted. You can select the following from the list:

- Last Known Good Value—Select this option to use the last known good value from the sensor in the flow calculation.

- Use Configured Defaults—Select this option and then specify the required settings in the AGA-3 or V-Cone Differential Pressure Properties, Static Pressure Properties and Temperature Properties sections.

NOTE: For flow computers prior to version 6.70, the value on sensor fail is always set to Use Last Known Good Value.

- Run Direction—this allows you to indicate the direction of flow, forward or reverse, for a meter run. The flow computer calculates flow rates and accumulates flow volumes for one flow direction only for each flow run configured. If you want to calculate flow rates and accumulate volume for another flow direction you need to configure a second flow run, using the same run parameters, but with an opposite flow direction setting.

Select one of the following from the combo box:

- Forward by Value— Select this option if the flow direction is forward when the value from a differential pressure (DP) sensor is positive or the mass flow rate value from a Coriolis meter is positive.

- Reverse by Value—Select this option if the flow direction is reverse when the value from a differential pressure (DP) sensor is negative or the mass flow rate value from a Coriolis meter is negative. When the flow direction is reverse the flow computer calculates flow rates and accumulates volumes for the flow run.

- Forward by Status—Select this option if the flow direction is forward when the Flow Direction Register has a value of 1 (ON) and the On Indication value is set to Forward. When the flow direction is forward the flow computer calculates flow rates and accumulates volumes for the flow run.

- Reverse by Status—Select this option if the flow direction is reverse when the Flow Direction Register has a value of 1 (ON) and the On Indication value is set to Reverse. When the flow direction is reverse the flow computer calculates flow rates and accumulates volumes for the flow run.

- Direction Status Register—Specify which register indicates the forward or reverse flow direction status. You can use valid registers for the flow computer controller for this setting. The default register is 1. This property is unavailable if the Run Direction option is set to Forward/Reverse by Value. This property is unavailable in GOST mode flow computers.

- On Indicates—this allows you to select either Forward or Reverse for the status register value. The default is Forward. The property is unavailable in GOST mode. The property is unavailable if Status Register control is unavailable.

The properties that you configure in the Inputs section are used for the differential pressure, static pressure, temperature inputs and the pulse input frequency when AGA-7 calculations are used.

- High-High Alarm—Use to specify whether high-high alarms are used for input variables to the flow calculation. You configure the actual alarm criteria in the individual input sections.

- Select Enable to use high-high alarms for inputs.

- Select Disable to not use high-high alarms for inputs. When disable is selected the High-High Alarm Threshold and the High-High Alarm Register fields are unavailable.

- High Alarm—Use to specify if high alarms are used for input variables to the flow calculation. The high alarm conditions are set in the individual input sections.

- Select Enable to use high alarms for inputs.

- Select Disable to not use high alarms for inputs. When disable is selected the High Alarm Threshold and the High Alarm Register fields are unavailable.

- Low Alarm—Use to specify if low alarms are used for input variables to the flow calculation. The low alarm conditions are set in the individual input variable tabs.

- Select Enable to use low alarms for inputs.

- Select Disable to not use low alarms for inputs. When disable is selected the Low Alarm Threshold and the Low Alarm Register fields are unavailable.

- Values in Alarm—Use to set the value for the input when the input is in an alarm condition. This is a global setting for input variables using alarms.

- Use Live Values—Use to set the variable input to use as the live value of the input when any of the alarm conditions are active.

- Use Default Values—Use to enable the Default Value entry for each variable input. The default value is used when any of the alarm conditions are active.

- Coil Alarm Output Indication—Use to enable the alarm output indication to use standard Modbus coil registers. When enabled, the alarm output indication can be set for differential pressure, static pressure, temperature and turbine measurement inputs.

NOTE: For Realflo version 6.79.1 this parameter is set to Enabled and the control is unavailable.

Further Information

For more detailed information on these properties, see the documentation provided with the RealFLO application.